David's Blog

ETZ Max Grinder (medium) Review

Dear Reader,

What Christian Etzinger has accomplished with his grinder designs is to transport the powder out of the machine into the porta-filter with perfect particle-distribution integrity. In other words, no micro-particle drift and no clumping. In addition there is no ground coffee trapped in the body of the grinder. (Only the unavoidable gram or two in the burr-set itself).

His unique dosing system impacts the grounds as they exit the burr set with rotating ramps. It makes a jet into the porta-filter below. The impact of the ramps consolidates the powder just enough to hold the fines. And the ground coffee is accelerated downward, through a short metal collar too fast to be affected by static fields if they existed in the metal. It is a perfect system for dosing.

In addition the grinder has a load-cell to grind by weight. When you reach the desired dosage (for us about 20g) the grinder shuts off automatically. This is a huge help to the pro-barista trying to control the flow-rate of the espresso into the cup because the flow rate is heavily affected by the dosage of coffee. (As I have mentioned many times the flow-rate is the holy grail: when it’s perfect caramelized sugars and distinct origin flavors are present in the crema. The barista is seducing the flavors into the cup with the perfect flow…) Any trapped grounds in the machine, or micro-particle drift during dosing, make it almost impossible to brew espresso at it’s fragrant peak.

So with the ETZ Max series the most troubling aspect of all on-demand grinders available today has been solved.

His second major innovation is to drive the “female” burr with the motor. All other grinders power the “male burr” (the cone) with the motor.

He is turning a small conical burr (32mm) fast enough to grind about 4g/second. All my experience with conical grinders would predict a very thin, watery extraction. (Maybe 40% of the efficiency of our DRM’s) However, because he applied the motor to the female burr the flavor intensity and crema viscosity are much better than they should be. (Maybe up to 80% of our espresso from the DRM’s) I find this quite remarkable.

Grind adjust is stepless with a coarse ring above a ring for finer grind adjustments.

So Dear Reader we are getting closer to having a true on-demand grinder that delivers full flavor from the coffee. I’m eagerly anticipating the Etzinger Super Heavy, featuring a 42mm conical burr set. And, I’m pleading with Christian to slow down the grind. With his innovation I think 3g/second grinding speed will be very efficient.

Staff Review

We put this little grinder on the bar at VIvace’s big locations…staff loved it. We train and train to

try to control the flow rate of the espresso and Etzinger’s Jet Dosing system allows perfect flow-rate control.

With any grinder retaining ground coffee in the machine you cannot control the flow rate, here’s why:

Coffee beans contain a natural moisture content even after roasting. Coffees with higher moisture content, such as Guatemalan Oriente, offer more resistance to the water flow and therefore require a coarser grind than an Indian Malabar to maintain perfect flow of the espresso into the cup. When ground coffee is in the grinding head it begins to lose moisture immediately due to ambient heat in the machine. So the longer the residence time of the powder the faster the water will flow through it. (Flow rate changes well before the coffee oxidizes). It is a nightmare for my baristi, trying to calculate how much the powder has changed between customers and purging powder that has sat too long. It is frustrating in the extreme and wasteful as well. (And don’t even get me started on clumping and particle drift due to static, both eliminated by Etzinger).

The grinder also vastly assists us by weighing the dosage accurately. Any change in the dosage also affects flow rate dramatically.

Staff loves that it is quiet.

And it handled our volume without shutting off due to overheating.

I’m beginning to get really pissed off that we struggle so hard to overcome problems with the grinders that are available. I am reminded of the dance we used to do to try to stabilize brewing water temperature before the PID revolution…

Sette 270 update

Dear Reader,

I have been using the grinder daily for over a year. The grinders ability to transport ground coffee into the PF without any disturbance of the particle distribution in the powder is the best I have ever seen. (See original posts). A true on-demand design that works.

However the small burr, 21mm, turning at a high rpm creates a new problem. The bean-feed is inconsistent. The bean hopper is not the problem here, the beans have a consistent column pressure entering the grinding head. I think the beans often bounce around before the burrs grab them due to the small size and high rpm. This creates two problems for the barista trying to control the flow rate into the cup. (Our goal is about 26ml in 25 to 31 seconds from 20g ground coffee)

First, as you probably know, turbulence in the bean feed creates a coarser grind, speeding up the flow rate. But critically the grinder is producing different dosages as the bean-feed fluctuates. And, as I remind my baristi all the time, achieving an accurate dosage is the single hardest technique. Perhaps the 270W, that weighs each dosage would be a good investment for anyone considering this grinder. (We tried weighing the dosage seperately and gave it up, too slow for Vivace in a slam).

Etzinger is making a commercial unit, the ETZ Max super heavy with 42mm burrs…perhaps the wait for a true gourmet on-demand grinder is over? My suspicion is that the rpm is still too high…I will let you know.

ROASTING IS NOT A CONCEPTUAL ART FORM

Dear Readers,

I’m having some serious fun exploring mild arabicas from all over the world. My primary interest is Ethiopian coffees. Lately we have sourced a Sidamo with extraordinary blueberry in the fragrance and the finish. And, every Sunday we offer a new single origin at our Brix and Alley 24 locations. So far Indian Monsooned Malabar is the hands-down favorite among staff and customers. (Look for single origin offerings on our website, coming soon for retail and wholesale customers).

As you may know our roast is modeled after the coffees I found in Northern Italy, high caramelized sugar content developed with the peak origin notes. Of singular importance is zero citric acid…

Roasting coffee is not a conceptual art form!

Speaking of citric acid it reminds me how embarrassed I am that many US roasters have adopted the undeveloped roasts dominated by citric acid. Some clown said “coffee is a fruit it should taste like a fruit”. ( Obviously it is not a fruit, it is a legume, a consumable seed of the coffee cherry). The flavor of these coffees is totally dominated by the citric acid present as the beans approach 2nd crack: it tastes like unsweetened lemon juice when brewed as espresso.

So this is the concept-“coffee is a fruit”. Roasters following this are blindly following a conceptual artist…Now when it comes to visual art an artist may have an eloquent concept to communicate such as ” rejection of materialism”. To transport the viewer into a state of reflection on their life they may employ jarring images or textures, deliberately abandoning sensuous beauty, and perhaps craft, to make a point. Western culture accepts this and artists then communicate important truths through their art. The viewer can easily turn away, choose not to look.

However a fine chef in Paris would never, ever make a bitter or sour sauce to drive the point home that life for the Parisian might be very sweet compared to most people in the world. OMG no….culinary art is in your mouth! It is visceral and powerful on an intimate level. A culinary artist must always seek to create pleasure in the participant first and foremost through an artful blending of flavors and textures to achieve umami-sensuous beauty in the mouth.

On-Demand Grinder Design

November 16th h 2016 Author: David Schomer, When all the factors are in control, machines are clean and temperature stable, coffee is fresh, barista techniques are solid, and grinder burrs are sharp, my baristi on the bar are mostly trying to control the flow-rate of the espresso oozing into the cup. To truly capture the fragrance of the ground coffee in a shot of espresso it must flow at a very precise rate into the cup. Ideally we want to extract about one ounce of crema in 26 to 29 seconds. And, the new generation of PID controlled espresso machines have revealed the exquisite sensitivity of the process to the speed of water passing through the ground coffee. Within our range of shot times we see dozens of different espresso profiles from the same blend. On the faster side, around 26 seconds, the caramelized sugars from the Indian coffee may come forward, a little slower, 28 seconds for the ounce of crema, and Ethiopian coffees may dominate the cup with a chocolate/umami. Shots that time out less than 25 seconds, “fast pours” are sour astringent at Vivace and shots that take longer than 30 seconds, “slow pours” may be hollow or have a bite to them. After 28 years of brewing espresso I am more fascinated than ever with the beauty and complexity of this method. For the expert baristi all over the world this is not big news. They have also learned that with the new temperature stable PID espresso machines, the flow-rate is what we must control to capture the fragrance of the coffee into the cup. And, we all struggle to control that factor. To control the flow-rate the grinder must produce the same particle distribution, and quantity of ground coffee each time we grind for a shot. Right now there is no grinder being made that can do this. Essential to artisan extraction is the practice of grinding each shot freshly. Commonly called “on-demand” grinding. At Vivace we have been grinding to order since 1988. This practice is now common to baristi from New Zealand to Taiwan, trying to make the finest shots possible. Although we now have stable espresso machines, the world-wide artisan espresso revolution does not yet have a grinder. Many on-demand grinders have been rushed to the market. They are simply modified, old style Italian grinders with the dosing hopper removed from the front. But to grind each shot individually, with a perfectly uniform grind, and dosage accurate to 1/10th of a gram, requires the grinder to be completely redesigned for this purpose. Many companies have placed a cone , or a vertical chute, where the old Italian dosing hopper used to attach to the grinder. In these machines the ground coffee must travel horizontally through some sort of chamber to the delivery cone or chute. This creates a machine with pre-ground “chambered-coffee” trapped within it. You cannot control the flow rate of the espresso if any ground coffee is trapped within the grinder. The on-demand grinder must dose straight down into the PF without the powder touching any metal surface.  This DRM grinding head clearly shows the chamber that traps about 6g of ground coffee on the way to the doser.

This DRM grinding head clearly shows the chamber that traps about 6g of ground coffee on the way to the doser.  Here we see the Anfim SP 450 without the doser cone. This grinder is being sold as an on-demand grinder but chambered pre-ground coffee equals almost 18g. The chambered coffee affects extraction in two ways. The first risk is ground coffee sitting in the machine, warm, and going stale. When it sits it also loses moisture. A dryer powder needs a finer grind. So, if it goes into your shot the dryer powder will offer less resistance to pressurized water, and the shot time speeds up. (Our window for a great espresso right now is 26 to 30 seconds to extract under one ounce (25ml) of crema. If the shot takes longer, flavor can go hollow, bitter, or sour. However, caffeine content is higher. The fast pours, under 25 seconds, are sour astringent, and the customer doesn’t even get the full caffeine. We always pitch the fast ones, serve some of the slow ones if they get the proper hang…at any rate my baristi are throwing out shots because the flow rate is too fast or too slow). The current crop of on demand grinders also face major difficulties getting the powder to the PF with out altering the composition between fines and the coarse flakes.

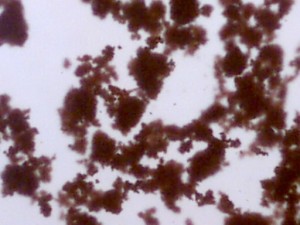

Here we see the Anfim SP 450 without the doser cone. This grinder is being sold as an on-demand grinder but chambered pre-ground coffee equals almost 18g. The chambered coffee affects extraction in two ways. The first risk is ground coffee sitting in the machine, warm, and going stale. When it sits it also loses moisture. A dryer powder needs a finer grind. So, if it goes into your shot the dryer powder will offer less resistance to pressurized water, and the shot time speeds up. (Our window for a great espresso right now is 26 to 30 seconds to extract under one ounce (25ml) of crema. If the shot takes longer, flavor can go hollow, bitter, or sour. However, caffeine content is higher. The fast pours, under 25 seconds, are sour astringent, and the customer doesn’t even get the full caffeine. We always pitch the fast ones, serve some of the slow ones if they get the proper hang…at any rate my baristi are throwing out shots because the flow rate is too fast or too slow). The current crop of on demand grinders also face major difficulties getting the powder to the PF with out altering the composition between fines and the coarse flakes.  Here is a micro=photo of the complete powder mix from a conical burr set. Fines are evenly distributed within a matrix of larger particles. As the coffee slides down into the PF static may affect its particle distribution. The static pulls the fines out of the tumbling mix because they have less mass, they are lighter than the bigger flakes.. What we need is true fidelity to the original mix of fines and coarse particles exiting the burrs.

Here is a micro=photo of the complete powder mix from a conical burr set. Fines are evenly distributed within a matrix of larger particles. As the coffee slides down into the PF static may affect its particle distribution. The static pulls the fines out of the tumbling mix because they have less mass, they are lighter than the bigger flakes.. What we need is true fidelity to the original mix of fines and coarse particles exiting the burrs.  Here is what happens as ground coffee is allowed to spray into the doser. Static electricity had caused finer particles to cling to the metal.

Here is what happens as ground coffee is allowed to spray into the doser. Static electricity had caused finer particles to cling to the metal.  This is a micro-photo of the particles that were clinging to the cone. Note it is predominately the fines. In conical grinding systems any static-electricity field the powder passes through traveling to the PF will affect the fine particles more than the larger flakes. (Conical burrs first grip the bean in the large fins and squeeze until it shatters, this produces particles of all shapes and sizes, including the smaller ones, called “fines”. Then, the bean is sheared to a consistent flake size with the finer teeth on the bottom half of the conical burr. But the fines slip through. Flat burr grinders are the choice for many baristi and grinder manufacturers like Mahlkonig, precisely because they feature more consistent flaking of the bean. It is true that conical burrs, producing fine particles, can make flow-rate control more difficult. However, the fines contribute much more flavor and a heavier mouth-feel in the cup and have always been our choice at Vivace despite flow-rate challenges). In the above picture you can see what happens if the coffee sprays out of the chamber, the fines separate and cling to the cone. And, lacking fines, the espresso pour speeds up, and the coffee thins out as well. To solve this the powder requires a gentle consolidation coming out of the chamber. This way the coarse flakes trap the fines in their original matrix. Static can’t separate out the fines when they are imbedded gently in the larger flakes. Consolidated coffee does not cling to the cone.

This is a micro-photo of the particles that were clinging to the cone. Note it is predominately the fines. In conical grinding systems any static-electricity field the powder passes through traveling to the PF will affect the fine particles more than the larger flakes. (Conical burrs first grip the bean in the large fins and squeeze until it shatters, this produces particles of all shapes and sizes, including the smaller ones, called “fines”. Then, the bean is sheared to a consistent flake size with the finer teeth on the bottom half of the conical burr. But the fines slip through. Flat burr grinders are the choice for many baristi and grinder manufacturers like Mahlkonig, precisely because they feature more consistent flaking of the bean. It is true that conical burrs, producing fine particles, can make flow-rate control more difficult. However, the fines contribute much more flavor and a heavier mouth-feel in the cup and have always been our choice at Vivace despite flow-rate challenges). In the above picture you can see what happens if the coffee sprays out of the chamber, the fines separate and cling to the cone. And, lacking fines, the espresso pour speeds up, and the coffee thins out as well. To solve this the powder requires a gentle consolidation coming out of the chamber. This way the coarse flakes trap the fines in their original matrix. Static can’t separate out the fines when they are imbedded gently in the larger flakes. Consolidated coffee does not cling to the cone.  Here is a simple cross-wire gate to prevent spraying coffee grounds by consolidating the powder with gentle back-pressure. Mazzer likes this solution and we employed it on the DRM as you can see. In theory, the wires should slow down and consolidate the coffee powder gently. However, with our roast, it worked poorly. True we did not have as many cling problems, but the stream of ground coffee could back-up making cakey blocks of ground coffee drop into the PF. If the coffee backs-up, the residence time of the powder in the burrs increases. The beans re-grind and become finer. Flow-rate control, our number one concern, is again destroyed when the shot seizes up. And, you can’t simply adjust for a coarser grind, each dosage of the powder will be different. After a couple of years we gave up on the cross wire gate. Back-ups were occurring way too often. We had another interim solution fail, and then arrived at this, the chain gate. ( Btw, if you are wrestling with a Mazzer caking on you, tear out the wires, and just hang a strip of scotch tape in front of the port, and see how you do. If it’s still cakey, softer tape for less resistance…)

Here is a simple cross-wire gate to prevent spraying coffee grounds by consolidating the powder with gentle back-pressure. Mazzer likes this solution and we employed it on the DRM as you can see. In theory, the wires should slow down and consolidate the coffee powder gently. However, with our roast, it worked poorly. True we did not have as many cling problems, but the stream of ground coffee could back-up making cakey blocks of ground coffee drop into the PF. If the coffee backs-up, the residence time of the powder in the burrs increases. The beans re-grind and become finer. Flow-rate control, our number one concern, is again destroyed when the shot seizes up. And, you can’t simply adjust for a coarser grind, each dosage of the powder will be different. After a couple of years we gave up on the cross wire gate. Back-ups were occurring way too often. We had another interim solution fail, and then arrived at this, the chain gate. ( Btw, if you are wrestling with a Mazzer caking on you, tear out the wires, and just hang a strip of scotch tape in front of the port, and see how you do. If it’s still cakey, softer tape for less resistance…)  At Vivace we tried this stainless steel cable chain gate on the entry to the doser cone. Sized at 1.5mm links separated by 2mm beads, it makes a perfect curtain to just consolidate the grind particles a bit, but not too much. Using the chain gate, we never have cakey coffee, but we are getting some cling on the cone as summer turns to autumn. We are running a fleet of 14 grinders and man do my baristi have to dance to try to maintain a perfect flow-rate while these issues affect the ground coffee consistency. They must always be conscious of the condition of the chambered, ground coffee within the machine. If it has sat too long, the barista must purge 6g out of the chute. And, if we get any cling we need to brush it out of the cone very quickly. We can’t lose the fines or the pour speeds up and thins out. They have a teeny cling brush. But the damage is done to the powder even if you brush the cling into the PF because the distribution of the fines in the mix has been altered. Looking at the pour under the bottomless PF will reveal the imbalance in the powder by having the pour favor one side or the other. With perfect powder the pour is always dead center under the PF. You know it’s beginning to remind me of the dance we used to do to get the machines to be more temperature stable. I remember we called it “temperature-surfing”. And the materials used in machine manufacture included porous brass they used for the PF and the group head. That stuff would trap oils and go rancid quickly. We had elaborate tool kits including green scrubber pads to clean the brass every 40 minutes of operation. Well, this grinder thing is beginning to feel like those old days before PID and stainless steel. We are getting tired of the dance to overcome equipment that is not made to grind-fresh for each shot. We all rosed our vices then, demanding temperature stable machines. It is time for artisan baristi all over the world to demand a grinder designed for us. However, if I am going to complain it is better to bring something to the table. I have found a design, the Sette (made by Christian Etzinger for Baratza) is a home grinder that solves the chambered coffee problem and the particle drift problem perfectly.

At Vivace we tried this stainless steel cable chain gate on the entry to the doser cone. Sized at 1.5mm links separated by 2mm beads, it makes a perfect curtain to just consolidate the grind particles a bit, but not too much. Using the chain gate, we never have cakey coffee, but we are getting some cling on the cone as summer turns to autumn. We are running a fleet of 14 grinders and man do my baristi have to dance to try to maintain a perfect flow-rate while these issues affect the ground coffee consistency. They must always be conscious of the condition of the chambered, ground coffee within the machine. If it has sat too long, the barista must purge 6g out of the chute. And, if we get any cling we need to brush it out of the cone very quickly. We can’t lose the fines or the pour speeds up and thins out. They have a teeny cling brush. But the damage is done to the powder even if you brush the cling into the PF because the distribution of the fines in the mix has been altered. Looking at the pour under the bottomless PF will reveal the imbalance in the powder by having the pour favor one side or the other. With perfect powder the pour is always dead center under the PF. You know it’s beginning to remind me of the dance we used to do to get the machines to be more temperature stable. I remember we called it “temperature-surfing”. And the materials used in machine manufacture included porous brass they used for the PF and the group head. That stuff would trap oils and go rancid quickly. We had elaborate tool kits including green scrubber pads to clean the brass every 40 minutes of operation. Well, this grinder thing is beginning to feel like those old days before PID and stainless steel. We are getting tired of the dance to overcome equipment that is not made to grind-fresh for each shot. We all rosed our vices then, demanding temperature stable machines. It is time for artisan baristi all over the world to demand a grinder designed for us. However, if I am going to complain it is better to bring something to the table. I have found a design, the Sette (made by Christian Etzinger for Baratza) is a home grinder that solves the chambered coffee problem and the particle drift problem perfectly.  Here we see the jet of ground coffee shooting out of the bottom of the grinding head in the Sette. Christian has his delivery mechanism attached directly to the bottom of the conical-burr set. But the coffee doesn’t tumble out it is impelled by an engineered disc with indented ramp areas. The coffee shoots out in a jet. The blades consolidate the particles and accelerate the stream of coffee so the metal collar it passes through cannot affect it even if it picks up a static charge. Making coffee on this grinder I always hit my flow rate. An experience I would like to have at Vivace. He has told me that he will come out with s commercial grinder, made to grind by the shot, in 2017. An on-demand grinder must also produce the exact dosage with each shot. Timers that run the machine for a set period of time are not accurate enough. To get a consistent dosage amount the grinder must shut off when the desired dosage weight has been reached.

Here we see the jet of ground coffee shooting out of the bottom of the grinding head in the Sette. Christian has his delivery mechanism attached directly to the bottom of the conical-burr set. But the coffee doesn’t tumble out it is impelled by an engineered disc with indented ramp areas. The coffee shoots out in a jet. The blades consolidate the particles and accelerate the stream of coffee so the metal collar it passes through cannot affect it even if it picks up a static charge. Making coffee on this grinder I always hit my flow rate. An experience I would like to have at Vivace. He has told me that he will come out with s commercial grinder, made to grind by the shot, in 2017. An on-demand grinder must also produce the exact dosage with each shot. Timers that run the machine for a set period of time are not accurate enough. To get a consistent dosage amount the grinder must shut off when the desired dosage weight has been reached.

Sette Update

After a couple months using the Baratza Sette grinder at home I see a slow shift towards a coarser grind occurring. (After several months I have been backed into the finest setting the machine can produce.) Kyle, the ever helpful owner of Baratza said they have noticed this as the burrs break in over time.

Currently, even at the very finest setting, I’m barely maintaining a 25 second extraction. Kyle says he has a kit to allow a spacer to be installed beneath the burr set. That will work. My only question is why isn’t the spacer installed before shipping the grinder?

Also, there is definitely chambered coffee within the grinder. Not very much, but a 4 g minimum purge is required in the morning to get that first shot to pour well. It makes sense, because any grinder used for on-demand grinding will have broken beans trapped within the burr set.

My recommendation: run the motor until all coffee is expelled each evening to have truly fresh grind in the morning.

The Naked Truth-reading your pour

The bottomless, or naked, port-filter is especially well named. Because there is no hiding: the entire integrity of the espresso program, from grinder burr sharpness, barista technique, coffee freshness and roast, and machine calibration is on display. There is no hiding using this porta-filter. And of course the closed, or traditional port-filter, is a huge metal surface contributing rancidity to your cup if it is dirty. So the naked porta-filter is the only choice for truly great espresso.

Above is an extraction on Nuova Simonelli’s T3 of our Vita blend. The grinder is the DRM mixed burr. The color density can be read and offers 100% fidelity to the actual flavor and strength of the shot. I have never seen a pour without some lighter spoking in it, but here it is very faint. ( Good luck getting an extraction to look like this). But the less whitish color and the more rich brown showing, the more flavor you have extracted from the ground coffee.

Whitish colors indicate this extraction was about 5o% efficient. Shot timing is OK, about 26 seconds for the one ounce shot. However, light color means about 1/2 the flavor potential of the ground coffee was destroyed during brewing or grinding the coffee. This color indicates a weak extraction but does not pin point the problem. It could be dull grinder burrs, stale coffee, or temperature drift during extraction.

This pour is timed at 20 seconds for one ounce, a fast pour. Lighter color may in this case accompanies a very sour flavor which I think is citric acid.

This pour timed out at over 30 seconds, a slow pour. Dark color overall indicated burned coffee compounds and the flavor might be hollow, bitter, or sometimes sour, but not citric-acid sour. Stream is favoring the right-hand side as we look at it, which is generally not good.

This pour times out at 27 seconds for the one ounce shot but is off balance. Offset stream indicates a crooked pack, or bad distribution of ground coffee before packing. On the left is blacking, indicating water flowing too slowly on that side and “burning” the essential flavor compounds, , on the right it is lighter indicating water flow is too fast on that side of the extraction.

Novmber Pro Barista Class

Hello expert baristi…we are planning our next Pro Barista class for mid November. Contact Jes at trainer@espressovivace.com to get a spot. We are limited to eight students, as always. Here is a picture of the last class to graduate, with students from New Zealand and Korea.